Packaging Machinery by CARTOMAC: solutions for carton box & cardboard box packaging

Since 1980, CARTOMAC has been working in the packaging machinery industry, and it is specialized in the automation of carton packaging.

We design and manufacture a comprehensive range of machines for carton box and cardboard box packaging, from standalone units to fully integrated production lines. Whether you need packing cartons for food, industrial, automotive or pet food products, our solutions guarantee precision, reliability and efficiency.

Advanced solutions for carton packaging

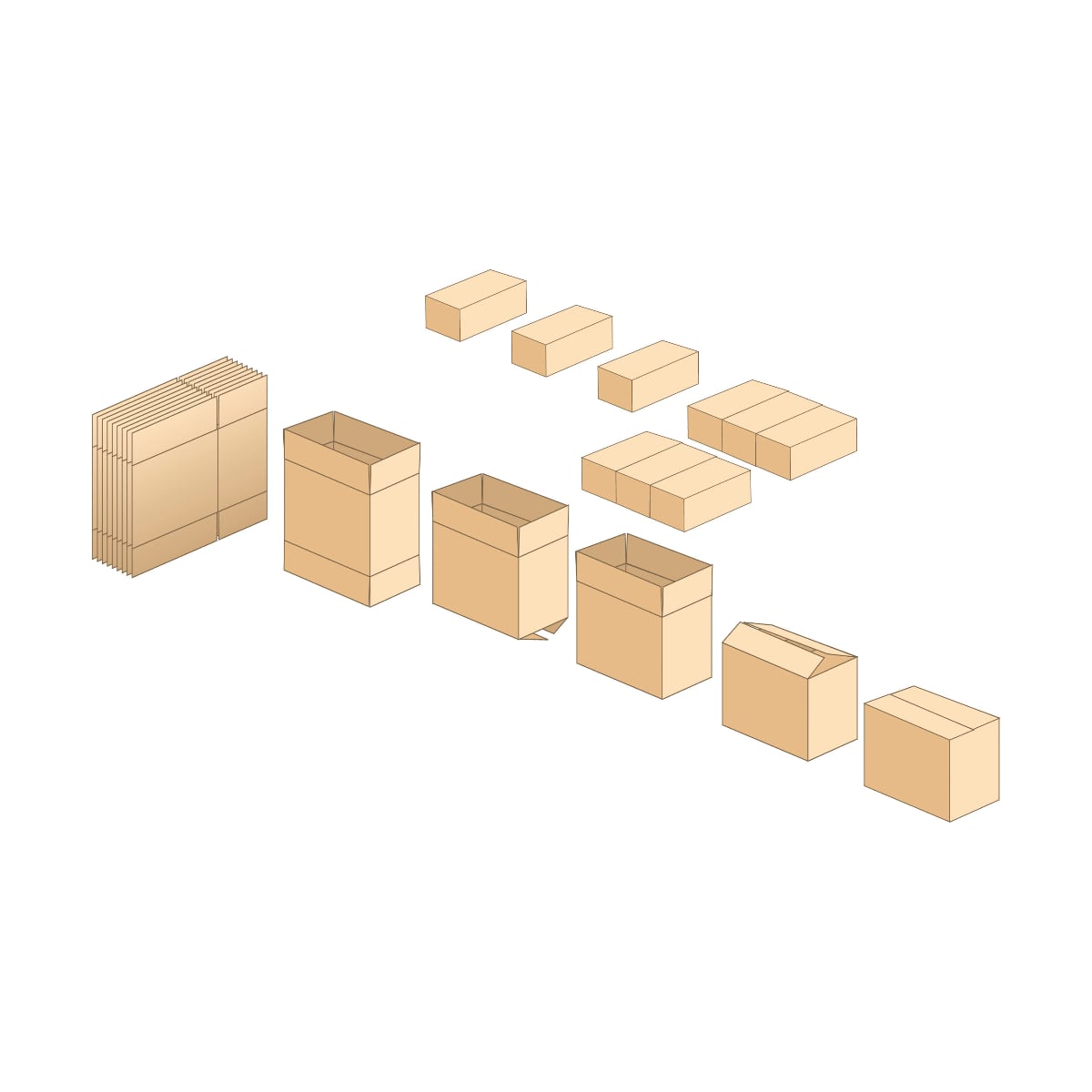

CARTOMAC machines are engineered to streamline the entire carton box packaging process. From handling empty cardboard boxes to preparing packing cartons for shipment, our systems improve efficiency, reduce downtime and ensure consistent quality across every packaging box. The automation capabilities of our equipment allow for precise control over cardboard box packaging operations, making it easier to manage production flows, reduce manual labor and maintain high standards for cartoon boxes, packing cardboard and other carton boxes. By optimizing the packaging process, our solutions help companies to meet tight deadlines, while preserving the integrity of each cardboard carton.

Why choose CARTOMAC for your packaging box needs?

Flexibility and customization: our machines are designed to adapt to different sizes of carton boxes, packing cartons and packaging boxes, from small units to large-scale cardboard box packaging operations.

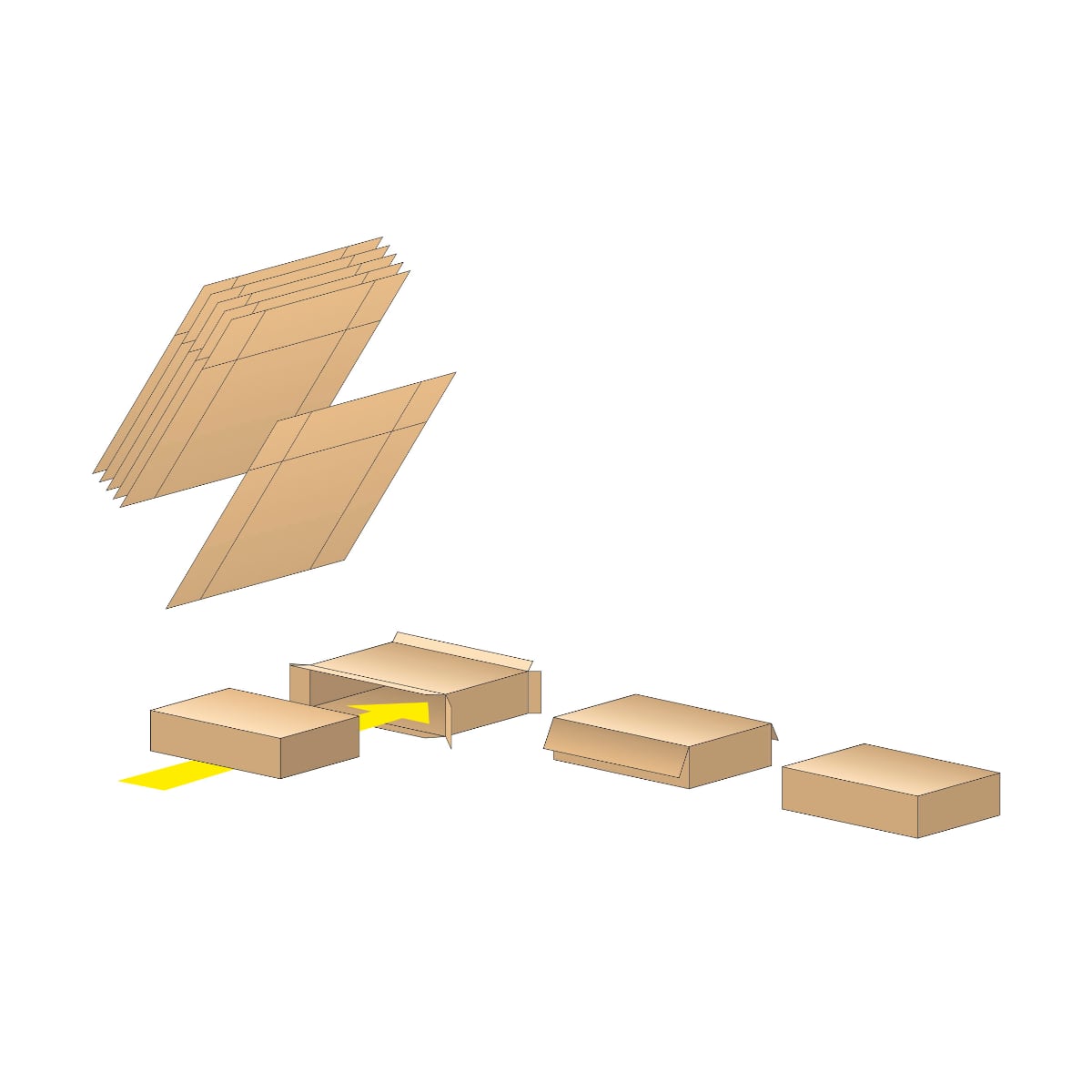

Modular design: you can choose a single carton forming unit or a full line that includes forming, loading, filling and sealing, depending on your production flow.

Reliability and quality: built with durable materials and engineered for long-term performance, our systems ensure precise handling of packing cardboard and consistent production of cartoon boxes.

Efficiency and optimized workflows: every machine helps minimize downtime and waste, ensuring a steady progression from empty cardboard boxes to fully sealed carton box or cardboard carton packaging.

A complete partner for carton packaging automation

Choosing CARTOMAC means relying on a company that understands carton box packaging at every stage: from the creation of empty cardboard boxes to the final sealing of the finished packaging box. Our experience and technical know-how allow us to provide the most suitable machinery for each production requirement, whether you need a single carton forming machine or a fully automated horizontal casepacker line.

Contact us to learn how our solutions can enhance your carton packaging processes with efficiency, reliability and long-term performance.

FAQ - Carton box packaging

What are boxes used for in packaging?

Boxes are used to protect, contain, and organize products during storage, transport, and distribution. They provide structural support, prevent damage, and allow for efficient stacking and handling. Boxes are essential for both consumer goods and industrial shipments, ensuring products arrive safely at their destination.

What is a carton box in packaging?

A carton box is a type of packaging made from folded paperboard, used to hold, protect, and display products. It can be printed, customized, and designed for shipping, retail, or storage purposes.

What is cardboard packaging or box packaging?

Cardboard packaging, or box packaging, refers to using paper-based boxes to contain, protect, and transport goods. It includes standard cardboard boxes, corrugated boxes, and custom carton boxes.

Why are corrugated boxes used for packaging?

Corrugated boxes are preferred for packaging because they are strong, lightweight, and durable. The fluted inner layer provides cushioning and impact resistance, protecting fragile items during shipping.

Are corrugated boxes good for shipping?

Yes, corrugated boxes are ideal for shipping. Their multi-layered construction absorbs shocks, protects against crushing, and provides stability during transit. They are widely used by manufacturers, e-commerce companies, and logistics providers for both domestic and international shipping.

How do you pack a carton or cardboard box?

To pack a carton or cardboard box effectively, start by choosing the right size box for the items. Place heavier items at the bottom, fill gaps with cushioning materials like bubble wrap or paper, and avoid overpacking. Close the flaps securely using tape or a sealing system.

How are cardboard and corrugated boxes manufactured?

Cardboard and corrugated boxes are manufactured from paper-based materials. Corrugated boxes consist of an inner and outer liner with a fluted middle layer for strength. Advanced machinery. such as CARTOMAC products, ensures consistent quality and precision in production.

How do you manufacture or make carton boxes?

Carton boxes are made by feeding flat sheets of paperboard into a carton forming machine, which folds, glues, and assembles the box into its final shape.

How do you make personalized or custom packaging?

Personalized packaging is achieved by adjusting the box size, printing logos, or adding custom inserts and coatings. Digital printing, die-cutting, and customized carton forming machines allow manufacturers to produce bespoke boxes tailored to brand requirements and product specifications.

How many types of boxes and cartons are there?

There are multiple types of boxes and cartons, including regular slotted cartons (RSC), half-slotted cartons (HSC), die-cut cartons, foldable cartons, and corrugated boxes of varying ply (single, double, triple). Each type serves a specific packaging and shipping purpose.

What is the difference between a carton, a cardboard box, and a corrugated box?

A carton is a paperboard container often used for retail packaging. A cardboard box is a general term for boxes made from thick paperboard. A corrugated box includes a fluted layer between liners, providing extra strength and protection for shipping.

Who manufactures cardboard or corrugated boxes?

Cardboard and corrugated boxes are handled by specialized packaging companies. CARTOMAC produces advanced machines for carton box packaging that efficiently form, fill, and seal boxes with products ready for shipment. These machines enable both standard and custom carton box packaging solutions for a wide range of industries.