Automatic cartoning machine

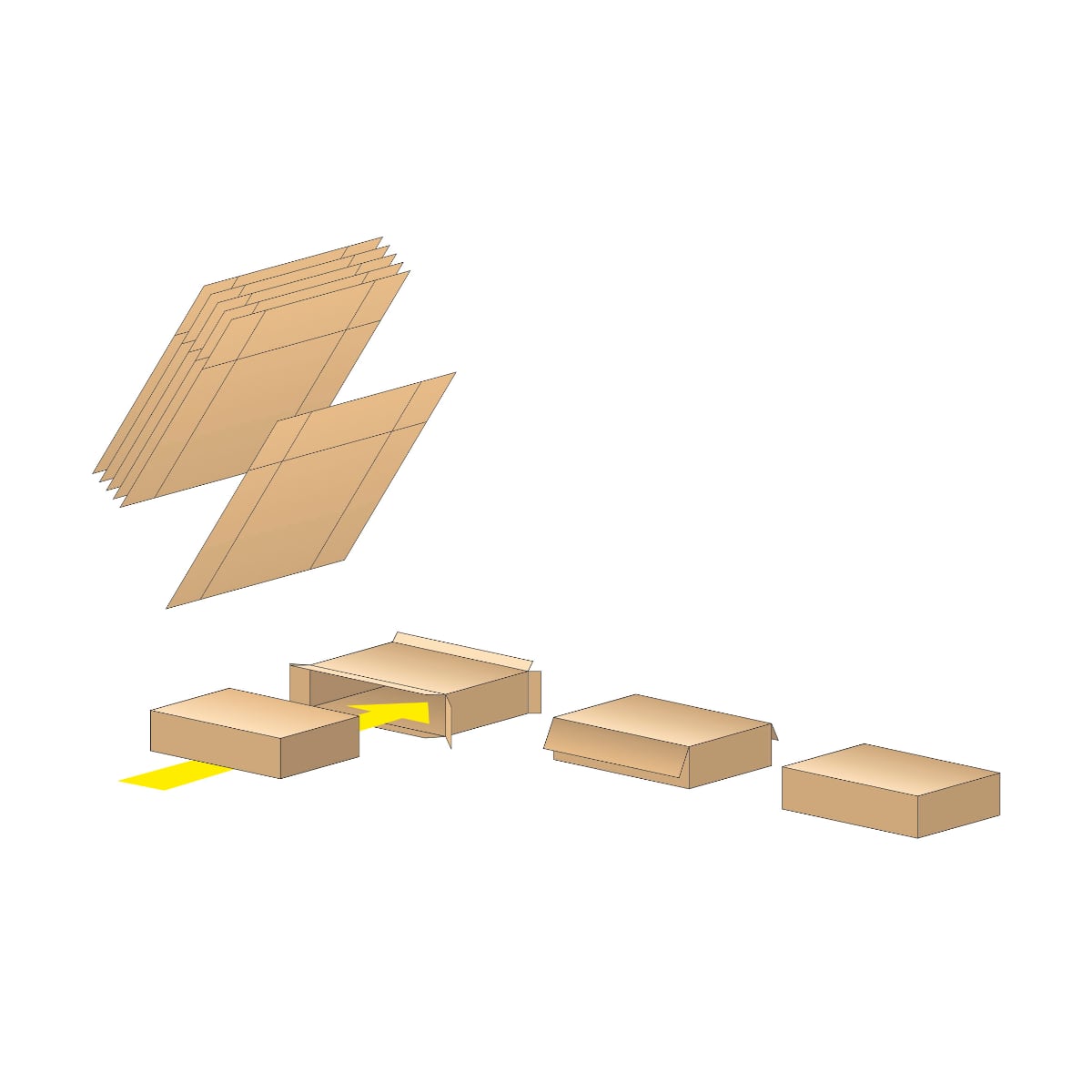

The horizontal cartoning machine model AS 220 automatically forms and closes boxes using pre-glued cartons. It essentially consists of an infeed conveyor with intermittent motion for product insertion, a carton magazine, and a second conveyor equipped with a device for inserting, folding and closing the box flaps. Product insertion on the conveyor can be either manual -carried out by an operator - or automatic by means of a synchronizing device.

Most of the groups the machine is made up with are adjustable, therefore on the occasion of a format change the operator does not need to replace all of them.

Description

- Mechanical and pneumatic operation

- Painted steel construction

- Adjustable bucket conveyor

- Infeed conveyor with adjustable pushers

- Carton magazine equipped with compacting device

- Alarm for detection of low level of cases in the magazine

- Alarm for boxes not open

- Box pick-up through sucker arm with Venturi system

- Arm for product insertion in the boxes equipped with safety system

- Mobile device for flap opening to ease product introduction

- No product-no carton feature

- Hot-melt glue closing or hook closing

- Handwheel and reference ruler for format change

- All parts in contact with the product are made of AISI 304 stainless steel

- Safety guards on all parts complying with CE normative

- Machine with CE marking

Video not available

To play the video, you must accept all cookies.

You can change your cookie preferences by clicking on the button below.

Manage Cookie Preferences

Ideal for the packaging of

Automatic cartoning machine: reliable packaging solutions

The use of a cartoning machine has become essential in modern packaging lines, especially in industries that require high-speed, precise, and reliable packaging solutions. Among the available packaging machinery options, CARTOMAC automatic cartoning machine stands out for its ability to streamline the process of forming, filling, and closing cartons with minimal manual intervention. An automatic cartoner machine is designed to handle a wide variety of products, from food items such as bars, snacks, and frozen foods, to non-food products including surgical masks and consumer goods. By integrating advanced mechanical and pneumatic systems, these machines can significantly reduce production time, minimize errors, and improve overall efficiency on the packaging floor.

A typical cartoner combines several key components, including an infeed conveyor, a carton magazine, and a device for flap folding and closure. The product can be inserted into the cartons either manually or automatically through a synchronizing mechanism, ensuring flexibility depending on the type of production line and product size. Most modern automatic cartoners feature adjustable components, which allow operators to make format changes quickly without replacing major machine parts. This adaptability is crucial for companies that produce multiple SKUs or need to adjust to seasonal packaging variations.

In addition to mechanical flexibility, automatic cartoning machines also prioritize safety and hygiene. All parts that come into contact with products are typically made of stainless steel, complying with food safety standards and facilitating easy cleaning. Not only: the advantages of implementing an automatic cartoner machine extend beyond speed and safety. By automating repetitive and labor-intensive tasks, companies can reallocate their workforce to higher-value activities, such as quality control and production planning. This not only increases operational efficiency but also reduces labor costs and the likelihood of human error. In industries with strict deadlines and high-volume production, such as organic food and automotive, the investment in an automatic cartoning machine often pays for itself in a short period through improved throughput and reduced waste.

In conclusion, automatic cartoners are highly versatile and can also be integrated into larger packaging lines to create a fully automated end-of-line solution. Investing in a cartoning machine - particularly a fully automatic cartoning machine - is a strategic choice for any company looking to enhance its packaging capabilities.