Automatic case erector with P

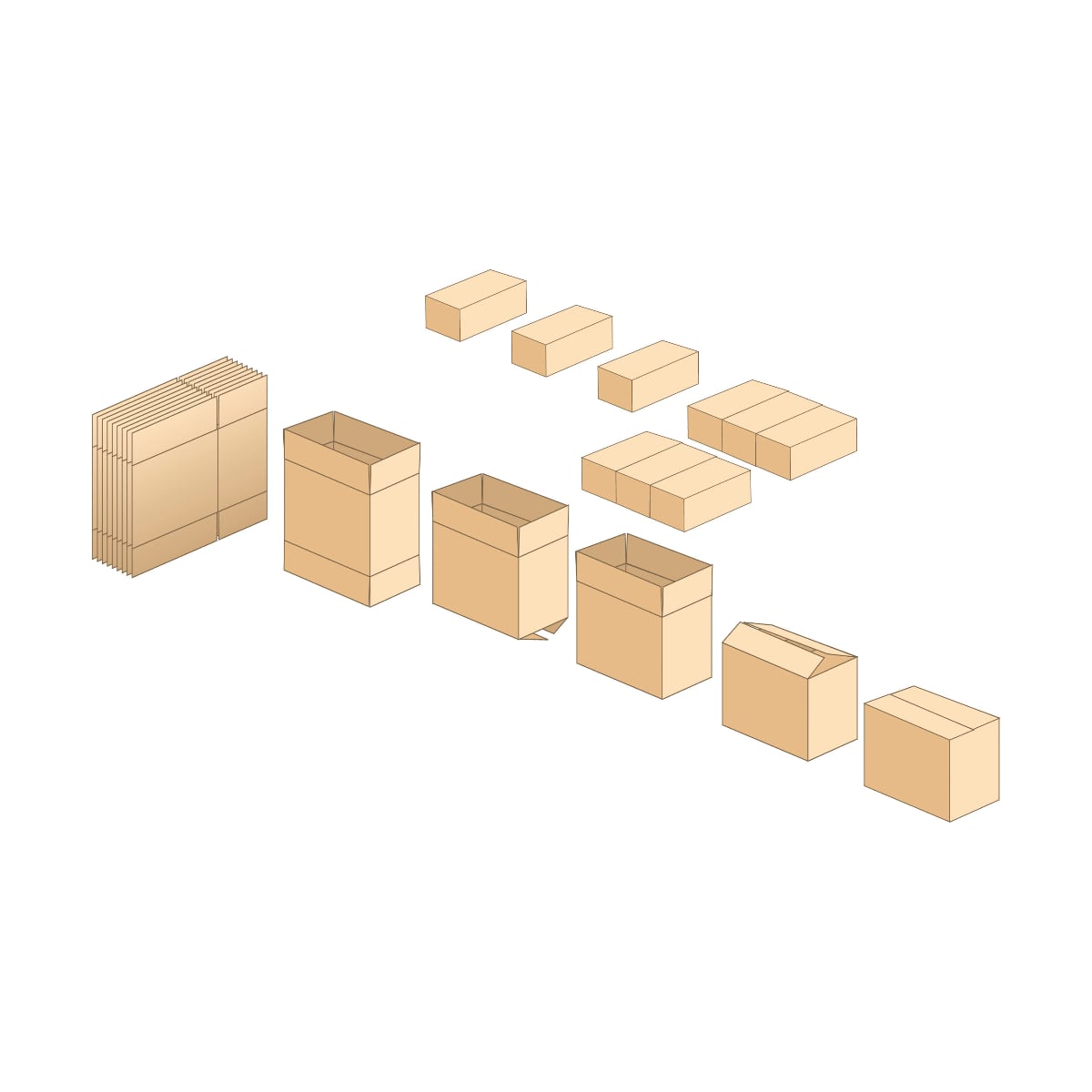

IT AUTOMATICALLY FORMS, FILLS AND CLOSES AMERICAN CASES (RSC).

Automation for cases forming through the closing of the four lower laps so that the cases are ready for vertical filling by means of an incorporated Pick & Place device. The forming device consists of a structure made of metallic tubes and painted panels with adjustable bases and supporting unit. Lower lap closing is done with adhesive tape or glue.

The carton magazine is in horizontal position; it has a capacity of about 100 cartons and it is equipped with an automatic feeding system to always assure the carton presence at the collection point. Adjustments for format change are carried out by means of handwheels. Cartons are opened by means of a pick-up head with suckers operated by a vacuum pump. Lap closing is done pneumatically.

All the pneumatic material the machine is equipped with, complies with ISO rules whereas its electric control board complies with EC norms. The product arrives from the packaging machine through a feeding conveyor-belt which subjects it to a dimensional control. Another conveyor separates the products to make the correct quantity be fed to form a layer. Product feeding is also managed by a compacting cylinder and a by-pass unit to allow manual operations.

The carton to be filled comes from the forming device on which some adjustable pneumatic stops and some photoelectric cells are mounted for carton presence detection and control. A centring funnel, with vertical movement, and fitted to ease the filling process, enters into the carton. The two-axle manipulator, driven by electric motors and controlled by PLC, collects the layers previously prepared to transfer them inside the carton and up to the preset deposit level. The product is collected by means of vacuum suckers or, alternatively, pneumatic pliers. All the pneumatic components the machine is supplied with comply with ISO norms and the electric control board complies with EC norms.

Description

- Painted steel construction

- Electro-pneumatic functioning

- Size-change adjustments through handwheels

- PLC-controlled electric installation

- Lower lap closure through either 50mm high adhesive tape or glue

- Carton magazine with pick-up sucker arm

- Safety guards on all parts complying with CE normative

- Machine with CE marking

Pick & Place description:

- Product conveyor-belt with variable speed controlled by inverter, and stop function to separate the product

- Pneumatic compacting device

- By-pass device for product unloading

- Centring funnel

- Pick-up head with vacuum or pneumatic pliers

- Pick & Place's movements controlled by an integrated PLC with controls and gearmotors

Video not available

To play the video, you must accept all cookies.

You can change your cookie preferences by clicking on the button below.

Manage Cookie Preferences

Video not available

To play the video, you must accept all cookies.

You can change your cookie preferences by clicking on the button below.

Manage Cookie Preferences